Beverage Coolers - Dispensers

INTRODUCTION

Chilled water, alcoholic and nonalcoholic soft drinks are an integral part of modern life.

People living on different continents around the world, different religions, nationalities and ages with pleasure drink cold drinks.

Chilled beverages sold/consumed in the following places: Restaurants (full service, limited-service), restaurants and bars (snacks and drinks), beverage (alcoholic beverages), table catering service on the road, theater (the theater company and theaters with dinner), stadiums, offices wineries and breweries, gas stations, coffee shops, hotels, schools and universities, casinos, open-air concerts, private landlords.

Production of the chilled drinks equipment grows especially rapidly in the last 20 years [1].

Large firms (manufacturers of beverage cooler and dispenser) are involved in this market. They include Lancer [2], Codifesa (Spain) [3], IMI Cornelius (USA) [4], ABC Technologies (USA), Fountain fresh international (USA). In addition, relatively small companies (in Austria, China, France, Greece, Italy, Japan, Norway, Portugal, UK, USA, Spain, Switzerland, Sweden and others) have successfully penetrated this market. Development and production of new designs of coolers drinks subsidized by Coca-Cola and Pepsi-Cola [1].

The main factors contributing to widespread adoption in our life of cooled drinks, in addition to consumer demand, are the following:

1. Comprehensive market research to develop a rational strategy for choosing the most appropriate model for the beverage cooler -dispenser (BCD) for each potential customer;

2. Choosing the correct location of the apparatus;

3. The calculation of the possible cash flow in each BCD;

4. Qualified service of each BCD by technical staff. This involves the installation of devices in the workplace, its running in and, if necessary, quick repair of BCD;

5. Special automated system for tracking sales of machines, ensuring a high level of service and the ease of maintenance by operator;

6. Using radio transmitters, antennas and Internet lines installed at BCD and allow to count money in the apparatus to conduct an inventory in remote locations by owners of BCD;

7. Simplification and significant, long-term improvement of the element base and schematics of BCD;

Thanks to new laws and regulations by governments, technical organizations and associations of various countries in recent years, can add to this list the following factors:

• Extensive use of materials and components are not harmful to human health;

• Reducing the harmful effects of equipment on the environment;

• Increased safety requirements of equipment installed in public places;

• Improving the efficiency of energy use and increasing the coefficient of performance (efficiency) of each newly installed BCD.

Despite the fact that for the consumer bottles of cold drinks are the most convenient product, chilled water and any kinds of cold beverages are widely sold in cans and on tap. According to specialists Zenith [5], the production of coolers and beverage dispensers with mechanical cooling system, insulated or no insulated, has already reached 3 million units in worldwide sales of over 2 billion liters, in 2007. Unfortunately, not found available summarizing the financial statements for the world production of chilled drinks. In addition, the distribution by types of beverage coolers and dispensers on the commodity market (for water, beer, spirits, soft drinks, etc.) is difficult. At the same time, a rough estimate of the market may reach 2 billion $US [5].

Given the aforementioned reasons, and a strong desire of world leaders to reduce dependence on nonrenewable sources of energy, the development and production of inexpensive and thermodynamically efficient BCD is very important and necessary direction for the inventors and developers of new technologies and cooling equipment.

ANALYSIS

The remaining analysis of the drink cooling methods intends to help inventors and developers to determine the benefits and drawbacks of the known BCD designs, reduce development time for new BCD models and, if possible, identify the most rational design of BCD. The design requirements for the development of a new beverage cooler - dispenser could be formulated with regard to the factors mentioned in the introduction. As a database for ongoing analysis, there were selected results of information retrieval in the library of the US patent offices as well as in Google.

The following key words were chosen to search for patents and papers:

1. ttl:/(beverage AND cooling), ttl:/(beverage AND cooler);

2. ttl:/(beverage AND bottle AND cooling), ttl:/(bottle AND fast AND cooling), ttl:/(can AND fast AND cooling), ttl:/(bottle AND cryogenic AND cooling), ttl:/(can AND cryogenic AND cooling);

3. Bottle fast cooling: Google;

4. Bottle fast cooling commercial report: Google.

The total number of found patents and documents is 210.

The accumulated data base is analyzed in terms of the basic technical requirements for the new design cooler-dispenser of drinks, packaged in bottles, cans or provided to the consumer/customer on tap. These basic requirements include:

• A high cooling rate (from a few seconds before 1 - 5 minutes);

• Compactness of the device;

• Safety standards;

• Health standards;

• Low energy consumption.

In addition, database analysis was conducted on the most effective way of cooling and selection of the most relevant patents. It is well known that the desired reduction of the cooling duration of the product can be achieved in the following ways:

• Lowering the temperature of the cooling medium, such as gas, liquid or solid cooling surface, being in direct contact with the outer surface of bottles or cans. Typically, this method requires a large investment, operating costs and a significant amount of energy to produce cold;

• Improving the quality of heat transfer and heat transfer coefficient between cooling medium and drink (an increase of heat flux and/or increased velocity of the cooling medium and the

• expansion of the boundary layer turbulence);

• Reducing the size of the cooled object (for purposes of this analysis, this method was not acceptable, because bottles and cans have predetermined different sizes and shapes).

I.1 Cooling by gas

Air coolers are most prevalent in the present. They are characterized by high quality of cooled bottles and possibilities for fully automation the process of cooling process and enough low prices. At the same time, cooling rate realized in well known air coolers (air temperature of about (4÷10)ºC) is low. In addition, rapid cooling of bottles with drinks by gas environment, has some disadvantages in terms of the present study, such as:

• Need to use a refrigeration unit to maintain a low evaporating temperature of refrigerant (about minus (30÷20)ºC), which requires substantial investment and energy costs.

• here is a danger of drink freezing, which leads to loss a quality;

• Low-value of heat transfer coefficients and the cooling rate in comparison with immersion of bottles and cans in the low temperature gas or liquid coolant;

• The need for high speed and pressure of the air flow, which causes increasing fan power consumption.

Realizing a direct contact of the low temperature nitrogen or carbon dioxide vapor with the external surface of bottles or cans as in domestic applications and commercial applications, is complicated. Complexity is of the refrigeration circuit apparatus, the temperature control system to prevent freezing of the beverage, and increasing the required installed power of BCD .

I.2 Cooling by direct contact with the evaporator outer surface

In coolers, realizing this method, the shape of the evaporator (made from copper, aluminum alloy or stainless steel) is chosen so that the cooling evaporator surface adjoined (closely connected) to the external spatial shape (silhouette) of bottles and cans. These BCD are not widely used. Each bottle requires a special form of the evaporator. The refrigerant boils in the internal volume of the evaporator. The coefficient of heat transfer between the boiling refrigerant and drink is low due to the presence of different kinds of thermal resistance, such as “refrigerant - wall of the evaporator”, "the wall thickness of the evaporator”, "contact of the evaporator wall - the outer surface of the bottle", "thickness of the bottle”, "thermal resistance of drink itself”. As the refrigerant could be used as usual, Freon-like (except ammonia) and cryogenic fluid (carbon dioxide, nitrogen) at a temperature of minus (60 ÷ 90)ºC. All the above-mentioned reasons cause the complication of the design of evaporator, increase the production cost of BCD, the difficulties in implementing the rapid cooling of bottles or cans, the emergence of the threat of accidents due to improper use of customer equipment with the presence of cryogenic liquids or exploitation BCD at very low temperatures.

I.3 Cooling by immersion in liquid

This type of cooling is widely known in the beverage industry. This method has several important advantages: high heat flow from the cooling liquid to the bottle, the relatively low investment and operating costs. At the same time, the immersion of packaged beverages in fluids has been limited in use due to operational challenges associated with high viscosity liquids at low temperatures, the difficulty to control the constant temperature of the liquid environment, safety and sanitary restrictions. One important non-technical shortcomings of this method is aesthetic display chilled bottles or cans after immersion in liquid compared with the beautiful glowing showcase in BCD with air cooling. In the apparatus, air-cooled, each client can open the door or a heat-insulating canopy and get the desired bottle or jar.

The last 10 -15 years characterized by major technological advances in increasing the rate of heat transfer and the development of innovative systems of automatic control of technological processes. This gives hope to create advanced innovative designs of the submersible type BCD. Theoretically, different kinds of liquids can be used for this method. These include: aqueous solutions with high concentration of additives (sodium chloride, propylene glycol, ethanol, invert sugar, glucose, fructose, ethanol, glycerol), as well as refrigerants, cryogenic fluids, including carbon dioxide, nitrogen.

However, the use of low-temperature fluids can cause freezing of drinks in a bottle or jar. That is why, it seems appropriate to exclude the immersion method of bottles or cans in any low-temperature medium (below minus 18ºC) (refrigerants and cryogenic liquids) from a list of potentially innovative ways of beverage cooling.

For the purposes of this study is of interest to the use of coolant in the form of two-phase medium - a liquid with tiny ice crystals. The technology of production of a given medium is called "Pumpable Ice Technology” - PI [6].

Using PI, we can reach very high values of heat flow, film coefficient between coolant and a bottle and the overall heat transfer coefficient (about 1,000 ÷ 2,000 W/(m² •K)) due to melting of ice crystals and the simultaneous absorption of latent heat of ice melting on the outside surface of bottles or jars. This coolant’s temperature can be minus (3÷5)ºC, a refrigerant evaporating temperature - minus (14 ÷ 16) º C. Thanks to these reasons, the rate of cooling drinks is very high, and, moreover, provided a uniform temperature distribution along the outer surface of the bottles and cans. At the same time, compared with conventional evaporator of coil type, the design of the evaporator-crystallizer (which creates pumpable ice) with a constantly rotating scrapers, is more complicated and less reliable. In addition, it increases the required weight of used refrigerant.

II. Considering the above reasons and purpose of the search, the found patents and publications can be classified as follows:

II.1 Of the more than 210 found patents and documents (information units), 193 (92%) can be divided into four categories: A. "Patents and articles related to the management and configuration of BCD”; B." Patents and articles related to the External design of BCD”; C. "Patents and articles related to: the indirect contact of liquid carbon dioxide and other cryogenic liquids with a cooled object; the construction of low-temperature household refrigerator”; D." Patents and articles related to the direct mechanical and thermal contacts of low-temperature liquids with the object (including bottles, jars and packaged food) to cooling and freezing”. Categories A and B, in the present study and at the stage of selecting the preferred cooling method of the bottles, cans or beverage on tap, not be thought of interest and not analyzed. For the reasons stated in paragraphs I.1, I.2, I.3, and based on thermodynamic studies of the effectiveness of carbon dioxide in small business [7], category C is uneconomical, and its implementation for home - a very dubious in terms of consumer safety. Despite the fact that the patents category D could be used and implemented in industrial conditions, none of them does not satisfy the requirements of the most important of this study: to cool quickly the product, in the shape of bottles or jars at home applications with low cost energy, and compactness of BCD.

II.2 The remaining 17 units of information can be analyzed in the framework of the present study.

II.2.1 In the following patents (U.S. 7,293,427: Beverage cooling apparatus and method; U.S. 7,281,392: Beverage-cooling device; U.S. 7,146,826: Beverage cooling apparatus; U.S. 6,681,594: Refrigeration apparatus for cooling a beverage; U.S. 5,974,825: Beverage dispenser with enhanced cooling efficiency , U.S. 5,456,387: Machine for dispensing chilled alcoholic beverage having improved cooling circuit and bottle mounting system) used well-known refrigeration circuit for cooling of drinks, hosted in bottles, jars, vessels, or for drinks flowing inside the coil and cooled by the outside of the refrigerant. Original technical solutions of these patents could provide a serious basis for the development of new BCD. However, one definite drawback inherent technical solutions presented in the above patents, in terms of the present study: total lack of any ideas for a sharp decrease in the duration of drink cooling. That is why patents in this group can be considered only as a "prior-art", i.e., "any information that was provided to the public in any form on the object of the invention before that date" [8].

II.2.2 The next group of articles and patents (U.S. 7,272,952: Beverage-cooling vessel; US 6,786,062: Beverage cooling device; U.S. 6,588,621: Beverage bottle cooling method and apparatus with assembly for holding ice and water; U.S. 4,607,502: Device for cooling containers, for instance beverage bottles or beverage cans, arranged in a wrapping; US 5,447,039: Beverage can cooling system; U.S. 5,201,183: Cooling device for beverage cans; U.S. 4,656,838: Cooling device for a can containing a beverage; and [9, 10]) are protected by the technical solutions that aim at improving the method of cooling of bottles or cans, convenient and suitable to domestic conditions. The proposed technical solutions are based on the use, in one form or another, previously collected and frozen improvised means (e.g., cubic, crushed ice or capsules with liquid nitrogen). This does not stipulate the use of refrigeration equipment operating in the "real" time. In addition, this group of patents is not formulated a technical solution to intensify the rate of drink cooling. That is why this group of patents also can be used only as a "pre-art."

II.2.3 The most important information units (patents and articles), from the standpoint of this study are as follows:

II.2.3.1 U.S. 5,237,835 “Installation permitting the rapid chilling (or heating) of packaged products, in particular of bottles”. Installation, which provides rapid cooling of fluids inside the container, in particular, inside the bottle. The installation consists of a tank, located in an isolated cell, which contains a special fluid. This fluid is maintained at very low temperatures by a special cooling schemes. Bottles or cans of beverages packed in special pockets. In turn, the pockets are placed in the cooling medium (liquid). Pockets are made from flexible plastic film sealed, "tight fitting" outer contours of the dishes with drinks, placed in the pockets. Thus, the achieved (due to good mechanical contact), reducing the thermal resistance between the cooling medium and drinks, which contributes to a significant reduction in the duration of cooling drinks. Added to this is that an increase in overall heat transfer coefficient can reduce the size of BCD. Applicant: Construction Metalliques Ardechoices C.M.A. (FR).

The proposed technical idea is similar to the objectives of our analysis: a method of cooling by immersing the object in a fluid (with temperatures above minus 18ºC), ensures rapid cooling of different forms of bottles, cans, and increases the rate of cooling drinks are offered on tap. At the same time, there is not any idea about a method of intensification of heat transfer between plastic pockets and chilled liquid, between the cooling fluid and the walls of the evaporator, as well as selecting the most rational design evaporator (in terms of reducing the installed capacity of the refrigeration compressor).

II.2.3.2 http://www.alibaba.com/product-free/100241379/Fast_Cooler.html

At the above site presented a device for rapid cooling cans, plastic bottles and glass containers with beverages to the required temperature. The device is loaded with the upper part and cools quickly (within 2÷10 minutes), wine, beer, plastic bottles and cans to the desired temperature. An important advantage is the possibility of simultaneous cooling of different drinks (bottles - up to three pieces) to different temperatures. However, the apparatus is so cumbersome (its trademark - "Fast Chiller"), which can be used, mainly in restaurants. Manufacturer - SRL, Ital Chill (Italy). Unfortunately, patent information and searches have not revealed a patent owned by "SRL, Ital Chill". At the same time, the idea and design of this device are very close to a possible technical realization of the previous U.S. patent 5,237,835.

BENEFITS OF SUBMERSIBLE TYPE BCD

As a result, patent and information searches revealed only one patent and one paper about the product of the global market which could be regarded as the most similar in conception to the discussed idea of economical, compact, thermodynamic efficiency, safety in operation, beverage coolers - dispensers. Of course, that the obstacles to creating such a device, you need to find ways of intensification of heat transfer from the coolant and from the refrigerant. In addition, have important technological and marketing challenges. Expected to choose the easy-to-consumer form of accommodation and storage of refrigerated containers or proper drinks. Necessary to enable the (optional) immediate withdrawal of the required number of bottles (jars) from the coolant. The client should not wipe wet cooled containers, and labels on the bottle or can must maintain high quality after removal from the apparatus.

To confirm the feasibility of invention and R&D activities in this direction, here are the advantages of the submersible type BCD (with the compressor-condenser unit) compared with all previously known beverage coolers and dispensers.

• In all existing refrigeration systems, used in modern BCD, applies the so-called scheme of direct throttling (TE) of the refrigerant. In the evaporator the refrigerant boils and evaporates, taking away the heat from the drink, along the length of the evaporator until the transition to a state of saturated vapor. Typically, this process is used (75 ÷ 85)% of heat transfer surface evaporator. The remaining (15 ÷ 25)% of heat transfer surface required (at least thus conducts the heat-technical calculations) for the implementation of the function of thermo-expansion valve (TEV) and protect the compressor. This function is to create overheating of the refrigerant vapor leaving evaporator with a temperature of (4 ÷ 6)°C. The nucleate (bubble) boiling regime (in a new design of BCD) will support, standing along the entire length of the evaporator, the maximum value of the film heat transfer coefficient. This will ensure using the evaporator heat transfer surface to 100%. The required superheat of the refrigerant vapor is realized in a, small and cheap, liquid refrigerant separator-regenerative heat exchanger.

• The film coefficients from the cooled liquid to evaporator (coil or plate type), and from the cooled liquid to the surface of the tube, through which beverage flows, or tank, in which drink is placed, are low. For example, the film heat transfer coefficient from the coolant is about (100 ÷ 500) W/(m² • K). This is explained by the fact that the velocity of the cooled fluid along the coil is small (≈ 0,2 m / s). The new design BCD can reach higher values of film coefficient of about (800 ÷ 1000) W/(m² •K).

• Substantial energy for the production and accumulation of ice formed on the outer surface of the existing evaporator (coil or plate type). Energy expenditure is about (120÷150) kWh/1,000 kg of pure ice. This is due to the fact that each new layer of ice is an additional thermal resistance in the selection of heat from the freezing liquid. This, in turn, leads to the need to reduce the evaporation temperature of refrigerant from minus (6 ÷ 4)°C to minus (16 ÷ 12)°C. At the same time, every 1°C to reduce the evaporating temperature corresponds to the drop in capacity of the compressor at 4%. Thus, lowering the evaporating temperature of refrigerant at 10°C leads to a 40% decrease in cooling capacity or to (15÷20)% increase in electricity consumption of the compressor. The projected temperature of evaporation in the new concept could be from minus 4°C to +2°C. In special cases, at the request of the client, evaporating temperature may be lower or higher than normal. Therefore, the specific energy consumption of the new BCD will be lower than in existing devices.

• The duration of the preparatory period (fluid cooling to the desired temperature and/or the production and accumulation of the estimated mass of ice) in the existing BCD is quite substantial. This is due to the inefficiency of this method of cooling fluid and the production of ice. For example, the reservoir water volume ≈ 60L, capacity compressor with refrigerant R-22 - ¾ hp (≈ 0,56 kW), the initial temperature of the coolant (water) - 30 ° C and the compressor efficiency ≈ 2, the minimum mode duration to produce 25 kg of ice, is 3.6 hours. The accumulated ice can is enough to cool drink at the maximum flow of 40 L/h and from the temperature of 30°C to 4°C during 1.6 hours. The total cycle time is 5.2 hours. Thus, it is possible to use dispenser with a storage ice tank at the maximum flow rate within 24 hours only a very short time 1,6 • (1924: 5,2) ≈ 7,4 hours. New design BCD of submersible type with condensing unit, allows to cool a drink with maximum flow rate continuously for 24 hours.

• Maintaining the final temperature in the range of beverage +(2,6)°C, but in some cases, close to the temperature of crystallization of the drink, due to the following requirements:

o - Slower growth of microorganisms;

o - Save the drink taste;

o - A sharp decrease in the amount of foam (for carbonated drinks and beer) while pouring into glasses.

In all known BCD, it is very difficult to maintain the final temperature of the drink which is close to its crystallization temperature. In the future construction of BCD with a condensing unit can be reached the final temperature of the drink, which differs from its crystallization temperature is not more than 0.5°C or at the request of the client, any other temperature.

• Thanks to improved refrigeration scheme, which is supported by a high heat transfer coefficient between the refrigerant and the beverage, in the new design BCD requires relatively small amounts of refrigerant. Compared with known design BCD manufactured by leading companies in the world, requires only (15÷30)% by weight of the refrigerant circulating in the refrigeration system.

• Efficiency of cooling (coefficient of performance) of any type known beverage coolers, dispensers, including the apparatus with a ice storage tank, is characterized by the following generalized coefficient

![]()

where

N - the energy required for drink cooling for 24 hours at maximum flow rate of the beverage, known values of the initial tin and final tf temperatures of beverage, kWh;

c - mass heat capacity of beverage, kJ/(kg • °C), (for example, apple juice, with c = 3.8 kJ/(kg • °C) = 0.908 kcal /(kg • °C));

tin, tf - initial and final temperatures, °C;

P - density of the drink, kg /L (e.g., apple juice, = 1.06 kg/L);

F - the maximum possible flow of drink, which is supported by the required final temperature of the drink, L/h;

- duration of continuous operation BCD within 24 hours, when BCD can operate at the maximum possible flow of drinks, h;

P - electrical energy consumed BCD within 24 hours (for apparatus with an ice storage tank, this energy stored in production of ice per cycle), kWh;

m - mass of ice accumulated during one cycle of BCD running, kg;

z - the number of cycles of ice production and accumulation within 24 hours;

r - latent heat of ice, 80 kcal/kg = 0.093 kWh/kg

By formula (1), we can calculate the efficiency of any BCD, for example, the apparatus with an ice storage tank COPdi. Then COPdi equals 0,4 ÷ 0,6 at maximum flow rate of drink (40÷50) L/h. This fact underscores that BCD with an ice storage tank works very inefficient and consumes energy twice that which is used exclusively for beverage cooling. For new construction of BCD, COPBCD, calculated by (1), is 1,9÷2,3 at maximum flow rate of beverage (300÷600) L/h.

• A perfect system of heat transfer from the refrigerant to the cold drinks ensures high efficiency of a new design apparatus. This, in turn, allows to develop and manufacture a compact, relatively lightweight device. Specific parameters of the supposed design BCD (footprint and volume) will be (35÷50)% compared with the known BCD.

• High turbulence and lack of "dead zones" in the coolant and beverage flows, reduce the likelihood of "fouling" surfaces in contact with the beverage, as compared with known designs of beverage coolers - dispensers. Even in the case of "fouling" surfaces, chemical cleaning is carried out effectively. In addition, all the heat transfer surface in contact with the beverage, is easily accessible for mechanical cleaning (this requirement is set forth in the regulations of the European Community).

CONCLUSIONS

1. On the basis of techno-economic criteria, including energy efficiency, cost, health and hygiene standards, an analysis of patent and scientific - technical information on existing designs of beverage coolers – dispensers is organized

2. In the present study was chosen as the most promising in terms of research and design work, the concept of immersion-type apparatus. We present the advantages of this design;

3. Submersible type of BCD can be recommended for cooling of bottles, cans, drinks on tap in various public places mentioned in the approach;

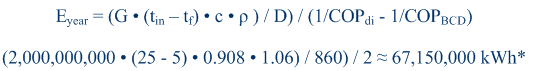

4. Taking into account all the aforementioned advantages of the construction of a new drink coolers - dispensers, we can assume that the indicative maximum annual energy savings from the use of BCD will be

where

G - annual consumption of beverages in the world, 2,000,000,000 L/year [5];

tin - initial temperature of the drink, 25°C;

tf - final temperature of the drink, 5°C;

c - heat capacity coefficient of beverage, 3.8 kJ/(kg • °C) = 0.908 kcal/(kg • °C);

- density of the drink, kg/L (e.g., for apple juice, = 1.06 kg/L);

D - conversion factor, 860 kcal/kWh

* This energy is sufficient for normal life support New York City for a full five months (according to [11] - consumption of electricity of New York in 2005 was 150.148 billion kWh). From the standpoint of economy of oil, this amount of possible saving of energy corresponds to 39,500 barrels of oil = 6,280,500 liters of oil [12]).

Acknowledgement

The author is indebted to Eng. Koren V., Dr. Avrukh L., and Eng. Katz G. for their interest and partial support of this work.

BIBLIOGRAPHY

1. http://www.vencoavendingmachines.com/vending_trends_update3.html

2. http://www.lancercorp.com

3. http://www.codifesa.com

4. http://www.corneliusuk.com/Corporate.aspx

5. http://www.reportlinker.com/d010999550/Global-Drink-market.html

6. http://en.wikipedia.org/wiki/Pumpable_ice_technology

7. http://www.epeeglobal.org/internet/docs/050920_StudyforEPEE_925.pdf

8. http://inventors.about.com/od/definations/g/prior_art.htm

9. http://gomestic.com/do-it-yourself/cooling-soft-drinks-and-beer-for-picnics/#5min;

10. http://www.coopercooler.com/demo.html

11. http://apps1.eere.energy.gov/states/electricity.cfm/state=NY

12. http://greenecon.net/understanding-the-cost-of-solar-energy/energy_economics.html