Calculation Of Pump-able (Slurry) Ice Machine Capacity

ABSTRACT

With pumpable (slurry) ice made from salt water solution, the ice production measurements were obtained for a range of ice concentration, solution flow rates and evaporating temperatures. The similarity theory was applied to obtain an analytical dependence of pumpable ice capacity on the essential parameters of ice machines. The proposed model can be recommended for rational design of the pumpable ice crystallizer constructions in the fish, food and chemical industries, supermarket refrigeration, thermal energy storage systems and production of ice wine.

INTRODUCTION

The Pumpable Ice (PI) technology [1] is well-known in the world from 50s of 20 century. The purpose of this technology is a production of a cooling medium (secondary refrigerant) with a viscosity of water and cooling capacity of ice. PI consists of water-based liquid and ice crystals. PI technology allows the lowest energy expenditure of ice production in comparison with all well-known ice production technologies (50 kWh per 1,000 kg pure ice in comparison with 90÷130 kWh/1,000 kg of flake ice), a high specific ice capacity per an area value of the evaporator cooling surface (up to 450 kg/(m2•h) in comparison with 250 kg/(m2•h) of regular ice maker construction) and an utilization of conventional water pipes and pumps. PI covers product around full surface and does not damage it. PI removes heat from product at significantly higher rates than other types of ice. The increased heat flux from PI causes long shelf life of products. These advantages resulted in the huge interest to pumpable (slurry) ice machine development and manufacture for ice accumulating in thermal energy storage systems (for energy saving and shifting of energy peak demand to the night), fish industry, air cooling of supermarket showcases, production of ice wine.

Usually, the equipment for the production, accumulation and supplying of PI includes an icemaker, an ice storage tank(s), a heat exchanger, a piping, pumps, electrical and electronic appliances and devices. The heart of this technology is a tube-in-tube evaporator (heat exchanger – crystallizer) in which ice crystals are produced into a volume of the flowing cooled liquid. In spite of many experimental and numerical investigations regarding the thermal-hydraulic characteristics of the PI evaporator [2, 3, 4], the industrial technical parameters of PI crystallizers are still unsatisfactory. It is required to support everyday engineering problems and to develop a single simplified method that allows the use of engineering judgment based on experience. It enhances ability to understand the relative impact of the main technical and technological parameters of PI production makers.

In this case, regular pumpable ice machines were tested. It was done by closing circle of PI production and simultaneous its melting in the storage tank in order to support the constant initial temperature of cooled liquid (2.5% ÷ 3.9% NaCl concentration in solution by weight). Experiments were organized for different flow rates, evaporating temperatures and initial temperatures of liquid (salted solution), final ice concentrations of the withdrawn PI (up to 50%).

Test Bench And Instrumentation Methods

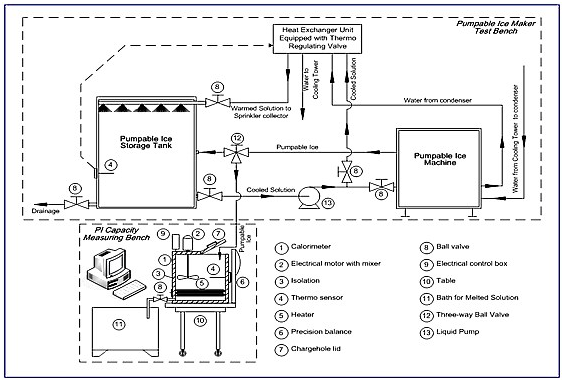

Test bench (Figure1) includes a 200 L cylindrical storage insulated tank (ST) with liquid sprinklers, tested PI maker with a water condenser, calorimeter for ice concentration measurement, cooling tower with pump and water accessories, pump for circulation of cooled medium from ST through plate heat exchanger and back to ST. Type-T thermocouples are installed to determine the temperatures of the refrigerant evaporating and condensing, liquid inlet to ice maker, PI outlet before ST, salted solution into ST. Flow meter with regulating valve are used for tuning of the liquid flow rate.

Figure 1. Schematic flow test bench

PI makers consist of several (from one to four) horizontal double-walled crystallizers-evaporators, with revolved rotor (shaft and plastic wipers) in each, compressor-condenser unit (with refrigerant R507A), refrigeration and liquid accessories including thermal expansion valve, valves, low pressure receiver, flow switch, flow meter, filters, solution pump, evaporating and condensing pressure control valves. Ice maker can produce the PI with ice crystal dimensions of up to 50 microns.

The tube-in-tube type evaporator is constructed of SS 316L. The inside wiped surface of the inside tube is polished (roughness corresponds to class N7 ÷ N9, it means about 1.6 ÷ 6.3 micron of the arithmetic mean deviation of a profile). The system is designed for sanitary connection. PI makers are constructed for a maximum test pressure of 34 bars (493 psi). A control system automatically eliminates the possibility of the freeze-up regime because of the liquid low flow rate.

All experimental data were noted only when the steady conditions were attained. In order to assure this, it was required that the measured difference between the evaporating temperatures tev in three successive measurements following each other in regular time intervals (10 minutes), should not exceed 0.1ºC. The same requirement was set forward for the final PI temperature. The duration of each experiment did not exceed 3 hours in which seven ice concentration measurements were realized. Ice concentration measurements are organized by methodic and caloremeter’s construction according to recommendations of ASHRAE [5]. The relative error of ice concentration measuring is 7%. The flow rate measurement is provided by accurate and precise flow meter, and absolute error of reading is 0.03 kg/s.

Experimental Conditions And Non-Dimensional Parameters

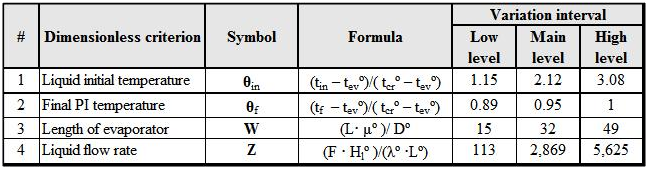

Apparently, all dimensional physical parameters entering in Table 1, in reality cannot assume an infinite set of different values. The latter lies within certain limits that were chosen, and is based on well-known experience in the development of the PI machine design and operation mode characteristics.

Table 1: Dimensional physical parameters

By dimensional analysis [6], four dimensionless criterions are obtained (Table 2):

Index “ º “ is main level of the dimension Physical Parameter (Table 1).

The goal function is the pure ice concentration (dimensionless value) of the liquid flow X=G/F.

Rules

Using dimensional analysis makes it possible to essentially reduce the number of independent variables and experiments, and therefore drastically reduces the volume of calculations and the amount of field experiments.

In order to study PI maker in more detail, we shall present the goal function X as a product correlation function of one-parameter functions (fi, i = 1, 2, 3, 4) of the selected essential parameters and a normalizing constant [7, 8]:

![]()

In order to find the explicit form of one-parameter functions and the constant factor we vary each parameter within the range of its admissible values and then process the obtained experimental results by the method of least squares, keeping all the other parameters at the main level. This yields the goal function X in the following form:

![]()

R² = 0.9975 (3)

Eq.(2) provides an apt illustration of the qualitative and quantitative influence of the essential design and technological characteristics (factors) on the intensity of the PI production process by manufactured PI makers.

CONCLUSION

• On the basis of the numerical solution of the experimental data, introduced by the similarity theory, there are obtained simple relations and the formula for the calculation of the Pumpable Ice production by ice maker with stainless steel 316L evaporators.

• The problem solution can be recommended as a rational model1 for calculating Pumpable Ice Slurry production in different applications including thermal energy storage systems, fish industry, and air cooling of supermarket showcases, juice and wine concentration.

Acknowledgement

The author is indebted to Eng. Koren V., Dr. Avrukh L., and Eng. Katz G. for their interest and partial support of this work.

REFERENCES

1. http://en.wikipedia.org/wiki/Pumpable_ice_technology

2. Kauffeld M., Kawaji M., Egolf P.W. Handbook on Ice Slurries: Fundamentals and Engineering. Paris, France (2005).

3. Stamatiou E., Meewisse J.W., Kawaji M. International Journal of Refrigeration, Vol. 28, issue 1, (2005), p. 60- 72

4. Egolf P. W., Kitanovski A., Ata-Caesar D., Vuarnoz D., Meili F. International Journal of Energy Research, Special Issue: Recent Advances in Thermal Energy Storage Systems and Applications, Vol. 32, issue 3, (2007), p. 187 - 203

5. ANSI/ASHRAE 29-2009 Methods of Testing Automatic Ice Makers, American Society of Heating Refrigerating and Air-Conditioning Engineers (2009), 10 pages

6. Sedov L.I. Similarity and dimensional methods in mechanics. Florida, USA (1993).

7. Guhman A.A., Zaitzev A.A. Generalized analysis. Moscow, (1998). (in Russian)

8. Fomin N.V., Menin B.M., Rzevskaya V.B., Guigo E.I. Drum freezing apparatus. Leningrad, (1986). (in Russian))

9. Menin B.M. Calculation of pumpable (slurry) ice machine capacity. Journal “Scientific Israel – Technological Advantages”, 2010, vol.12, No. 2 CIVIL & MECHANICAL ENGINEERING, p.178 – 181. 1 We haven’t dwelled here on the proof of the existence, uniqueness and stability of the optimal solution. Thus the paper is concerned with the rational and not necessarily optimal regimes of Pumpable Ice makers.